There has been a noticeable surge in the demand for materials that have remarkable energy efficiency and can endure extreme temperatures, as the industries continue to progress. Insulating firebrick, which forms a part of multiple processes in an industry, is already spearheading this change. The purpose of this article is to introduce the role of insulating firebrick into the context of the future of industrial applications, together with the advantages and innovations brought by this material and efficiency in operations that it drives.

Insulating fire brick is useful in high temperature industry operations such as in steel making, ceramic and petrochemical industries as it minimizes heat loss and therefore it is required in high volume in such industries. It is projected that with the rising focus on environmental conservation and effective energy use as a goal, the use of such bricks would exponentially grow. In addition to providing better heat insulation these bricks also reduce energy losses which is crucial for modern industry.

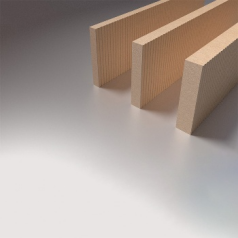

The world we live in is changing thanks to the Among the most recent advancements in material science include the absolute innovation of new insulating firebrick which is said to improve performance levels in the brick industry. For instance, there came the lightweight insulating fire bricks, which has completely transformed the approach of industries towards thermal management. This light-weight option has made it easier to handle and install the bricks due to their superior insulation properties with less weight. This invention does not just make logistics easier, but also helps to minimize the structural weight on industrial machinery.

Furthermore, The ever-growing demand for high insulative fire brick applications is the most reliable predictor of the future of insulating fire bricks. With industries trying to advance more and more in their thermal resistance the insulating fire bricks ought to change and grow. Following this pattern, manufacturers do currently offer fire bricks that with have a burning point of over 1800۠°C, because of these, it will be advantageous to operate in elevated heat environments. This potential for expansion is instrumental for industries such as aerospace and energy production for extreme circumstances are common.

On top of the performance improvements made in the development of insulating firebrick, the market appears to be at a focal point whereby emphasis is also put towards sustainable means in their production. To this effect, many companies are providing the market with eco-friendly products made from recycled materials and conserving emission during the production. Not only does this trend comply with sustainability objectives set on the global scale, but it is also attractive to those clients who do not wish to bear the expense of bad sourcing practices. As industry players continue realizing the impact of their productive activities on the ecosystem, the need for firebrick that is environmentally safe is bound to increase.

In the future, another key trend that we are likely to witness is the application of smart technologies within insulating firebrick. As far as advanced applications of insulating firebrick are concerned, one such the smart firebrick that registers any fluctuation in temperature and send the data to the users may not be far off. Such innovations will provide new opportunities for industries to enhance their processes even more, increasing safety and efficiency. Employing data analysis, the firms will be able to select decisions that will enhance the operational parameters of the company while decreasing the downtime.

Summing up, the reconstructive potential of insulating firebrick for industrial use looks rosy while being material driven, sustainable and smart. Insulating firebrick bricks will be at the forefront of meeting energy efficiency and operational targets as industries move towards bettering thermal management. Those organisations that put money in these advanced materials will see enhanced performance and at the same time will want to shift towards ‘greener’ industries.